Kurz is exhibiting Recopound, a recycled, injection molding PET grade. #sustainability

Leonhard Kurz will be exhibiting its Recopound resin in October at the Fakuma trade fair in Friedrichshafen, Germany. Recopound is a polyethylene terephthalate (PET) resin, recycled from postindustrial material. Injection Molding Pellets

Kurz offers a return and recycling program that reprocesses used PET carrier film residue sourced from customers of its surface finishing products. The resulting PET Recopound product is formulated for injection molding and suitable for durable goods.

Clothespins made from Kurz’s Recopound recycled PET material. Photo Credit: Leonhard Kurz

Customers remove the transfer carrier at the end of the finishing process. Kurz collects the material when a sufficient quantity is accumulated, and brings it to its in-house recycling plant, located at the company’s headquarters in Fuerth, Germany. There the carrier is then agglomerated and recycled mechanically with additives to make the Recopound material ready for injection molding.

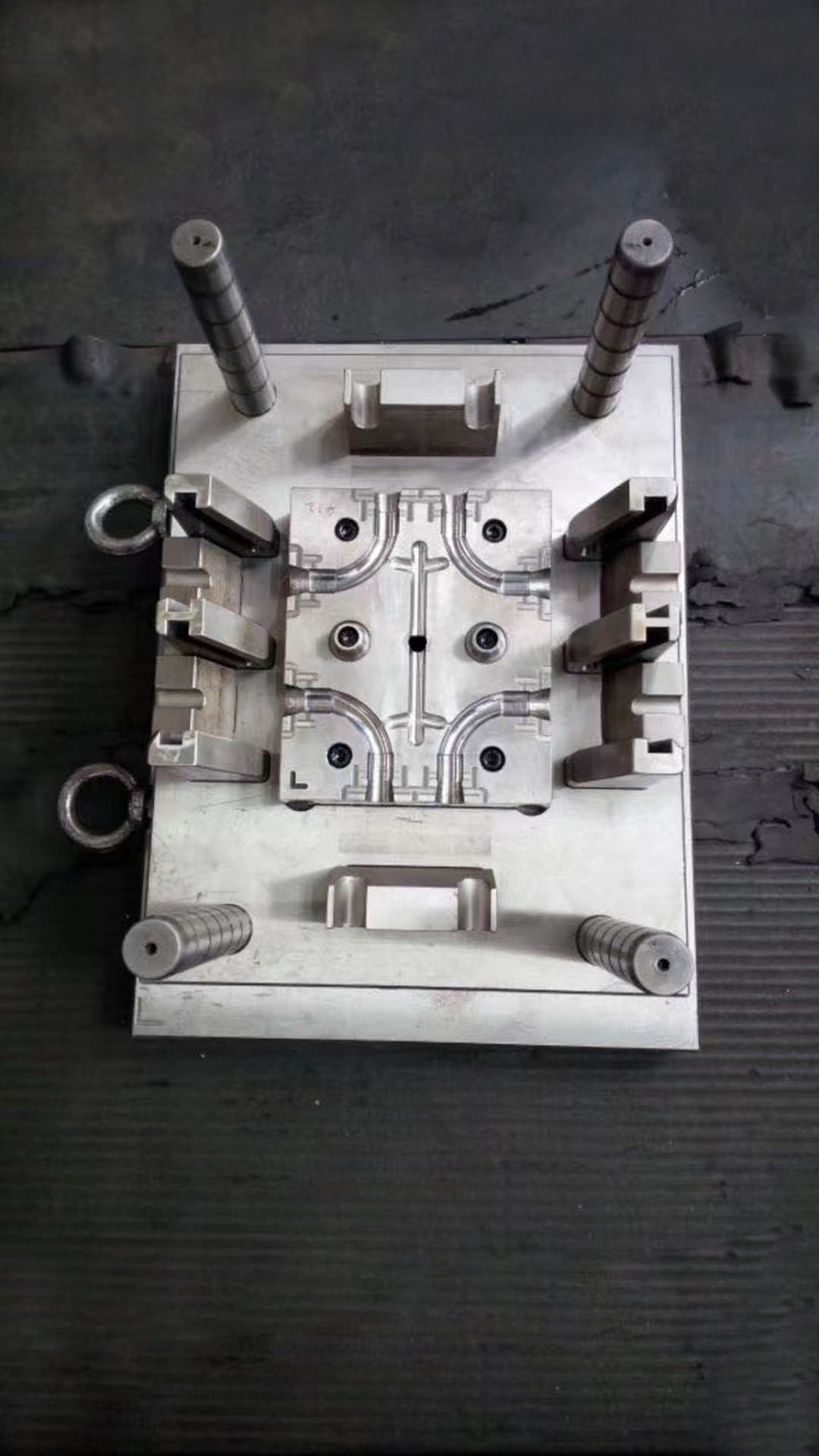

Exhibits on display at Fakuma 2023 will include clothespins produced from Recopound and finished with hot stamping in collaboration with Deckerform, toolbox parts produced by Arburg, and a window box developed with Munich-based startup Greenling.

The newly established branch in Ho Chi Minh City gives the German maker of injection molding machines 36 locations in 26 countries worldwide.

MTMS has acquired all the rights for the patented plastic melt temperature measurement system for injection molding from Schmit Prototypes.

Jörg Stech will be responsible for the company’s injection molding division with a focus on Europe and responsibility for the global development of the technology.

Vacuum Molding Plastic © 2023 Gardner Business Media, Inc. Privacy Policy [Log On]