The dumbest way to accidentally hurt yourself, or die, is to have a gravity-based mishap. Because as a species, we figured out that gravity could kill you way before we got to swordfights, shark attacks and driving Porsches into trees. Some early caveman was climbing a cliff and showing off, he lost his footing and plummeted, and the other cavemen learned a valuable lesson while poking his unmoving body with a stick.

That's why I don't bungie jump, skydive or apply for roofing jobs. I prefer to die the American way, which is from heart disease due to poor diet, not some stupid physics-based reason that your eulogist has to write his way around. Refractory Anchors Incorporated

I also don't want to fall down stairs and injure myself. Here on the farm there are a couple of outdoor wooden staircases that are like a good Bon Jovi album. So I'm looking at design solutions for making them less slippery, of which there are many.

If you're starting from scratch, using metal is an effective (and expensive) solution. Diamond plate steel like this is a popular choice.

However, perforated aluminum seems to me like it would offer more grip. This design looks incredibly effective, though if you did manage to slip on it, it would probably not make for a comfy landing.

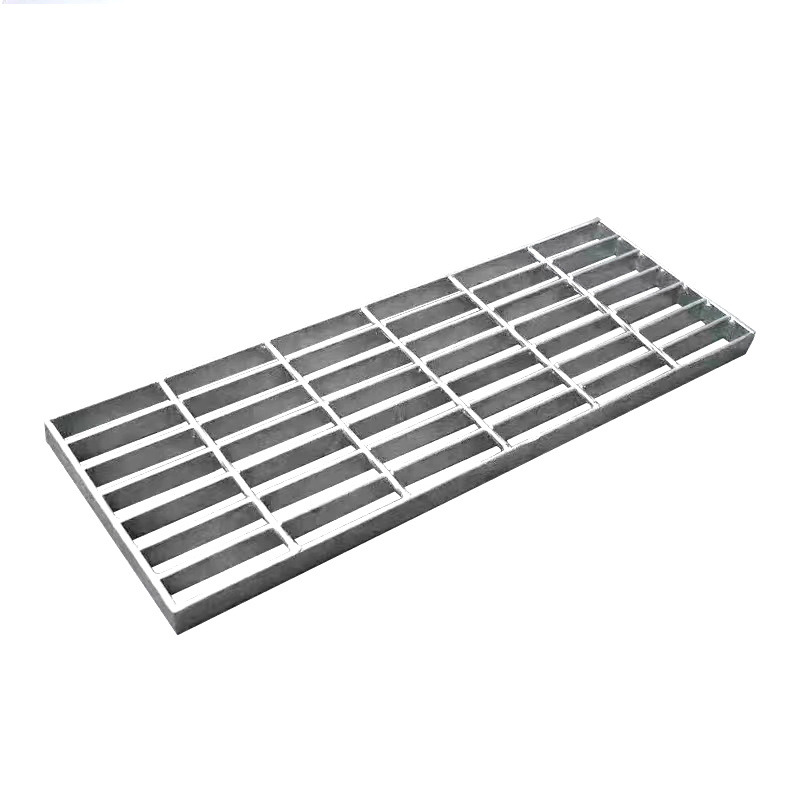

For very muddy applications where drainage is paramount, you can purchase expanded carbon steel sheets like this and cut it to suit.

For retrofitting existing stairs, a metal solution is perforated aluminum sheets like these.

The little raised volcanoes provide grip.

These aluminum strips can also be had in brightly-lit colors for better visibility.

The advantage of going with metal is obvious: Durability. But if it's not in your budget, less expensive solutions exist. These textured treads are made from fiberglass and have much to recommend them: They're retrofittable, offer a choice of medium or coarse grit and feature bright yellow on the nosing for visibility.

Those are affixed to the stairs with construction adhesive and a caulking gun. For a far easier installation, you could purchase rubber mats that simply lay on top of the stairs. These are probably fine with rain and snow, but presumably a pain to clean out if mud is involved.

Going even simpler, at the big box home centers you can purchase inexpensive anti-slip tape.

A DIY solution is to mix sand in with paint, and apply that to your (wooden) stairs to provide some texture. You can also purchase rubber or polymeric plastic grits to mix in with the paint.

Lastly, I came across this DIY solution: The unknown person who did this appears to have routed out a channel in their treads, and inlaid a rubber strip.

I am going to have to go with one of these solutions before winter comes, so if you've got a tried-and-true method you recommend, please do sound off in the comments!

Paint doesn't have the strength required to hold sand for very long, especially if you're shoveling. For non-slip applications on exterior surfaces, you should use an aliphatic urethane coating that will stand up to cleaning abuse and retain the grit. Epoxies generally aren't advised for exterior applications. You can also add a reglet with a carborundum strip for additional traction. This creates a little bump that your footwear treads will catch on. This is what we'll install on polished concrete floors which can be slippery when wet. The bump also provides feedback to users who are visually impaired that they're about to reach a change in elevation.

If you are looking for an "agricultural" (quick/cheap/effective) method, you can wrap the treads in chicken wire. This is very durable and very cheap if you have large expanses of decking. And if you don't mind the rustic look close up it's virtually invisible from any distance.

Here's what we use for non-slip stairs in a food manufacturing plant, where the surfaces are perpetually wet (and not just wet, often wet with cleaning agents that makes things slipperier. https://www.slipnot.com/products/stair-treads-and-covers/ They also make nosings to put at the front of an existing tread - our main entry stairway is porcelain tile with SlipNot nosings mortared in.

I would replace the rubber strip option with these: https://www.ebay.com/itm/KEENOVO-Silicone-Heater-Flexible-Heating-Element-Strip-Belt-15X4200mm-200W-220V/271283649964?hash=item3f29c3fdac:g:aIsAAOxyaqlSQETx

There is a reason teak has been used for years on boats. Wood in general is a nonslip surface it is when the stairs do not have the correct rise/run, are freshly oiled, covered in moss/algae or other issue that they become slippery. Also take into account that if you are going to be shoveling snow off said steps, anything short of the expanded steel to let the snow through when stepped on, is likely going to be damaged and/or make the ice start and stick much more easily than just plain wood. As it is said, just because you can doesn’t mean you should.

If the surface is primed for it the anti slip tape works really well.

The correct clear polymer beads can also be mixed into a polyurethane or other clear finish to add grip without detracting from your (possibly) unpainted, natural stairs.

I concur with Stephen, there exists filler material for paint that provides grip. Think fine plastic sawdust. I'd think sand is too hard, damages the paint too much if it comes loose. I've used the plastic filler dust on my (admittedly indoor) stairs and it works great.

Also, for painted surfaces there is a ground walnut shell powder that can be added for even better (read more irregular) grip and texture - plus it's a great up-cycled/natural product.

Test it out; it only takes a single click to unsubscribe

Doris Dev is a New York and Hong Kong-based product development agency with a proven track record of...

Formation is a product design + development company focused on human centered design innovation. To ...

Our goal as a full service industrial design studio is to create designs that emotionally connect wi...

Brainchild Engineering, based in Northville MI, is a product development and engineering company ded...

PDR is a major award-winning, multidisciplinary international centre for design and research with a ...

Anvil Studios is a product design firm for the real world. Anvil is Treasure Hinds and Greg Janky. ...

DesignBranch is a full service industrial design firm. From helping inventors and startup companies...

Don't have an account? Join Now

Already have an account? Sign In

By creating a Core77 account you confirm that you accept the Terms of Use

Please enter your email and we will send an email to reset your password.

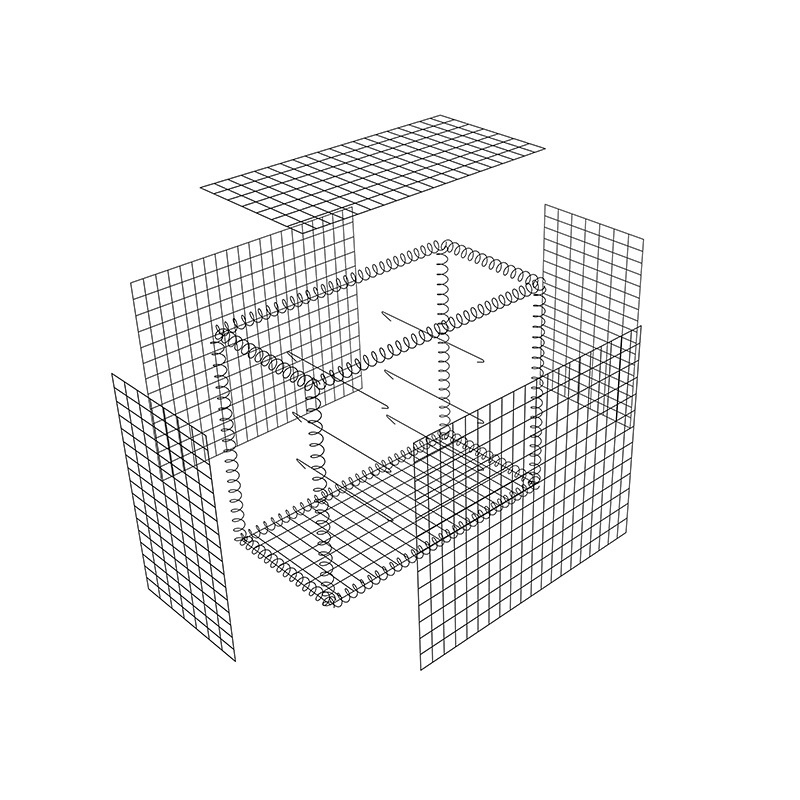

Welded Wire Mesh Test it out; it only takes a single click to unsubscribe